1948 – 195 Porsche 356/2 Gmünd Coupé – Ultimate Guide

With lessons learned from 356 No. 1, Porsche developed the 356/2 as a production-ready version. The biggest concession to useability was repositioning the engine back behind the rear wheels as the original VW design. Like 356 No. 1, 356/2 was built as two-seat roadster using VW parts.

The steering, brakes, suspension, transmission, clutch and headlights were all sourced from Volkswagen. The 25 bhp engine was bored, fitted with larger valves and fitted with a higher-compression cylinder head to produce 35-40 bhp. Later into production Porsche sourced hydraulic brakes from Lockheed for the front brakes.

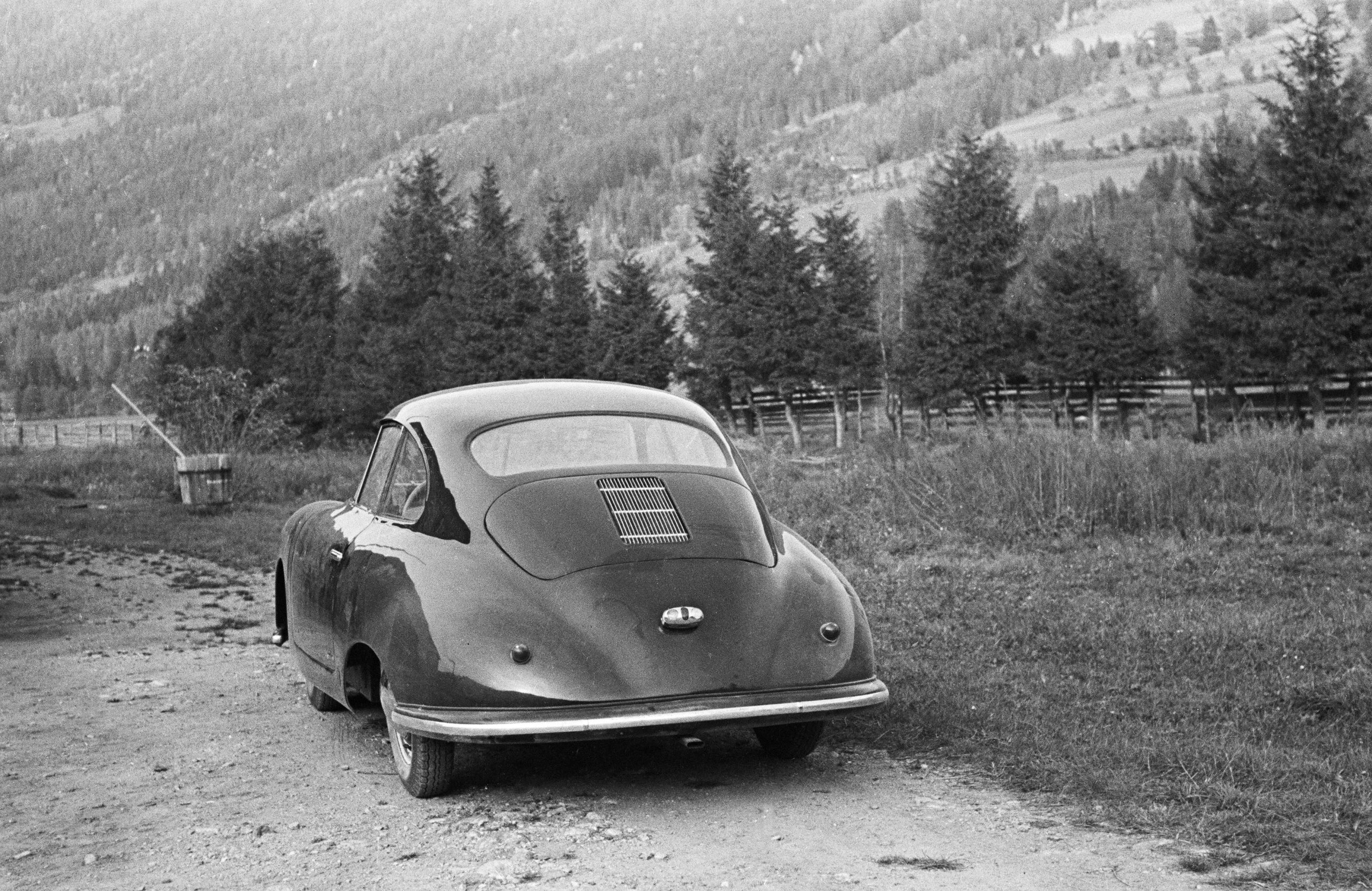

Unlike the tubular steel frame of the prototype, 356/2 was designed as a unitary steel tub which featured deep load-bearing sills, suspension pickup-points and mounts for the engine.

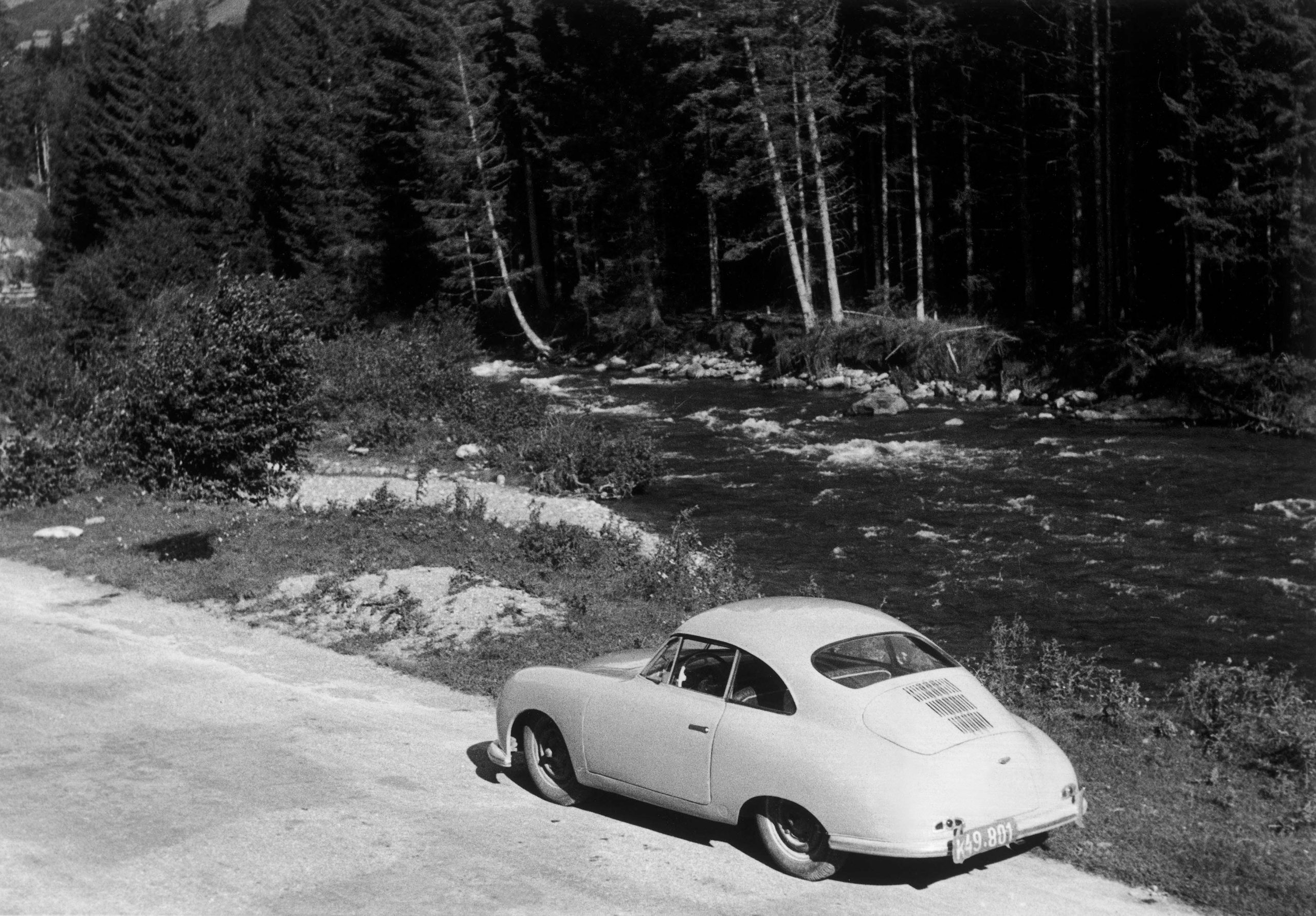

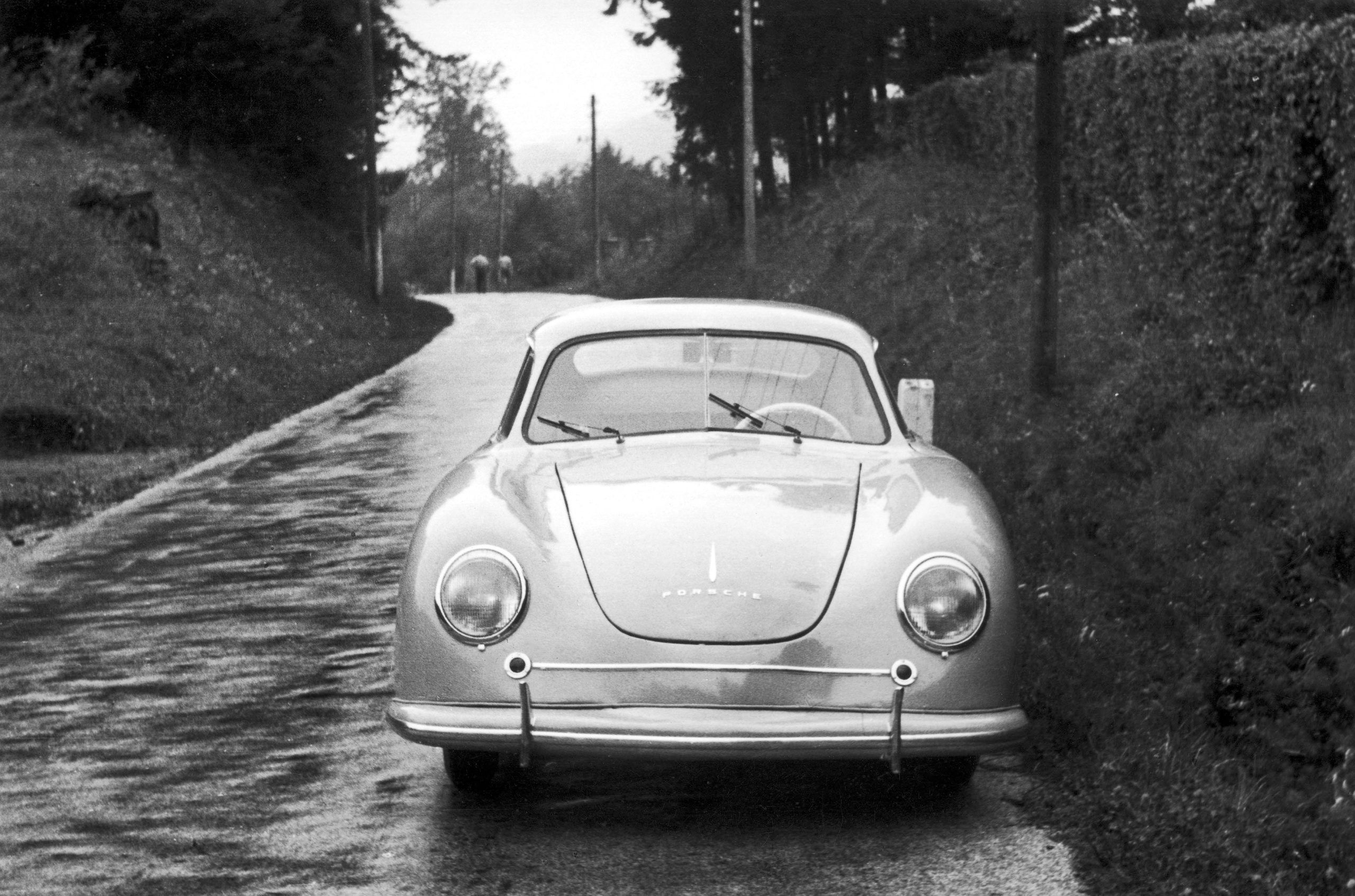

Due to the repositioned engine, the 356/2 was shorter than the prototype. The Erwin Komenda body was similar to the prototype, but had much longer rear overhang.

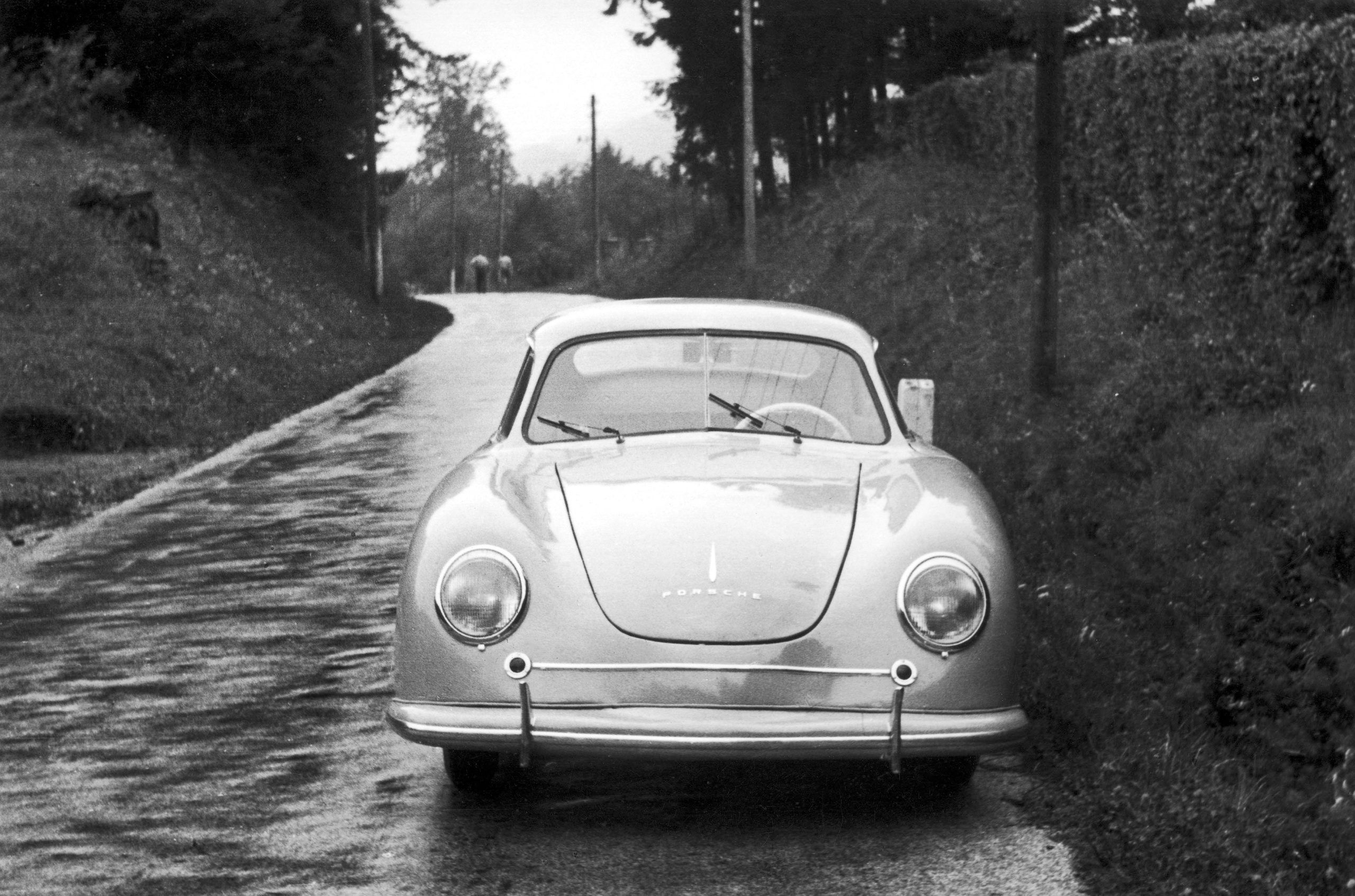

Both a Coupé and Cabriolet were initially drawn up and went into production. Details such split windows, integrated bumpers, curved quarter windows and two small accent strips between the front indicators were typical of the Gmünd cars.

The first cars were funded by Swiss businessman and Rupprecht von Senger who paid for the first 50 cars and he bought the first Roadster to be launched at the the Swiss Grand Prix of 1948. With production shifting toward Stuttgart, the cabriolet bodies were all outsourced: six chassis were sent to Beutler by Bernard Blank for cabriolet bodywork.

Later bodies were produced by Karosseriefabrik Ferdinand Keibl and Tatra in Vienna who produced only two additional cabriolets and several of the last coupes.

In 1949 Porsche completed a new cylinder head for the 356 based off the Strumboot design for the light attack boats. These allowed for 38mm valves over the 38mm VW counterparts and increased power to 40 bhp. With a slight increase in bore, this setup offered the same power, only 200 rpm sooner.1

Porsche oversaw chassis development of the 356 while their fabricators worked hard at making coupe bodies. When the aluminum bodies were found to be too time consuming the production was outsourced.

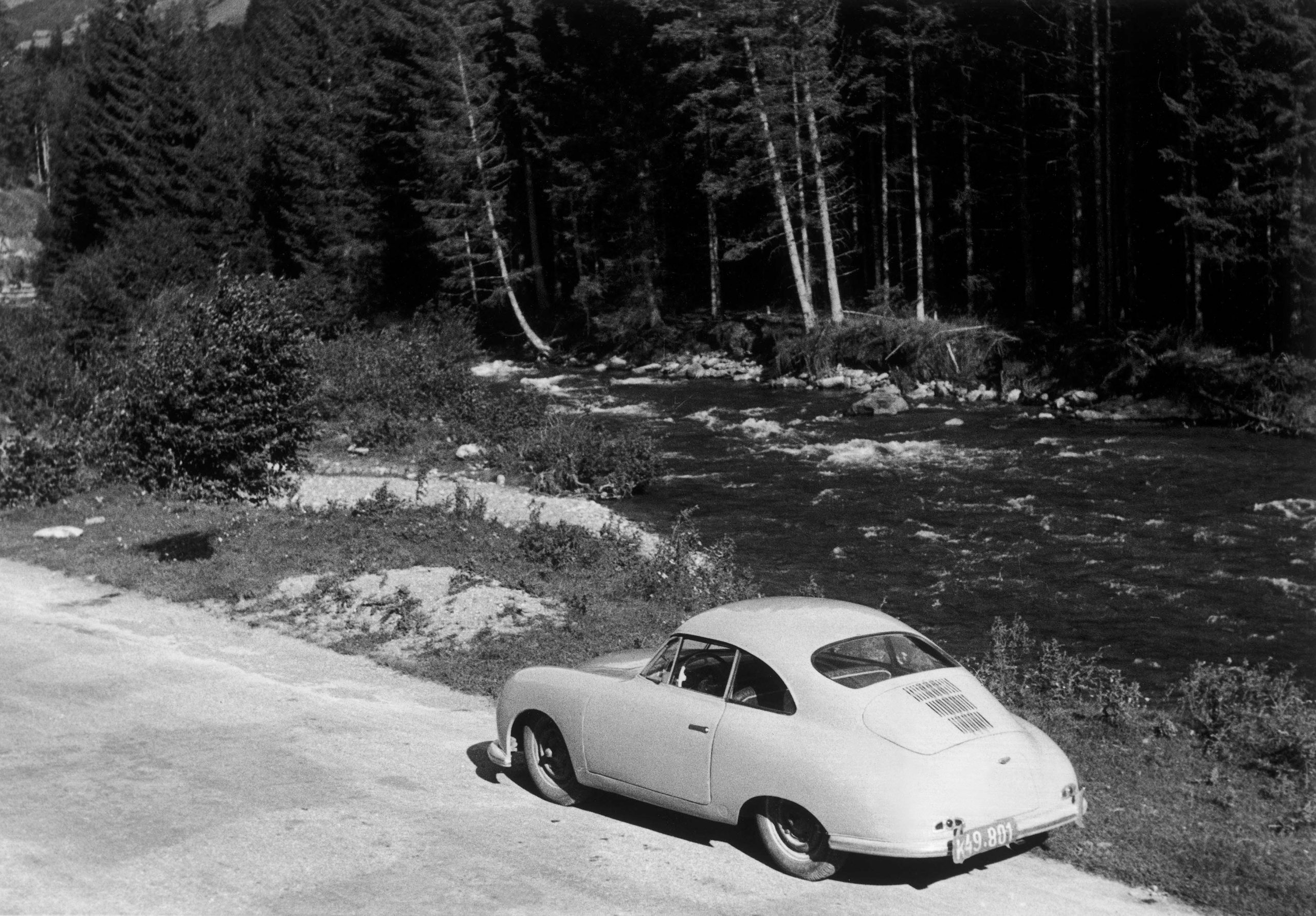

Deliveries of the 356 began in 1949. That year two cars were shown at the Geneva Auto Show in March. The Motor responded by calling it “One of the smartest little cars of the show” and described it as having “the lowest floor and seating position we have seen in any non racing machine.” With its relatively high cost compared to a VW, the Porsche was selling based on the merits of Ferdinand and the higher costs for British and Italian sports cars.1

Most of the first cars were sold in Austria and Switzerland. 15 cars later went to Sweden as part of a deal with Scania-Vabis which took their final car in 1951. Total production of Gmünd cars was 50 cars, eight being cabriolets and the other 44 being coupes. Production resumed in Stuttgart with steel-bodied cars in 1950.

The first Porsche 356/2 cars were produced in almost unbearable conditions in the wooden barracks that made up the plant, nicknamed the ‘Vereinigte Hüttenwerke’ (‘Hut Works Incorporated’).

Here in the Austrian town of Gmünd, around 300 workers built the first series-produced Porsche sports cars in the winter of 1948/49. An investor had already been found in Zurich in the form of Rupprecht von Senger, who put up the money in advance for a small series and in return was given the contract for imports to Switzerland together with Bernhard Blank. These two figures also helped with the purchase of materials, in particular when it came to the aluminium sheets for the bodies. A total of 52 cars were produced: 44 of these were 356/2 Gmünd Coupés and eight were 356/2 Gmünd Cabriolets. Unlike the one-of-a-kind 356 ‘No. 1’ Roadster with mid-engine, the 356/2 models featured a rear engine, making space for luggage and seats occasional use in the back. The complex tubular frame of the ‘No. 1’ was replaced by a steel box frame, but the body was still beaten out by hand from aluminium sheets. Modified Volkswagen components were used for the engine and chassis.

To say that the conditions for the production in Gmünd were difficult would be an understatement. There was a lack of machines and also often of materials, and the wooden barracks were bursting at the seams. Space was so tight in the machine barracks that workers could barely squeeze between the lathes. Even outsourcing some of the bodywork and completion processes to small specialist firms such as Beutler, Kastenhofer, Keibl or Tatra only slightly eased matters. On top of this, the transport and customs expenses for the components needed from Volkswagen in Wolfsburg were a hefty financial burden. Ferry Porsche later said of this that ‘there was zero profitability in Gmünd’. Since there was also insufficient land in Gmünd for essential expansion of the plant, the decision was made to return to Stuttgart. Although Plant 1 in Stuttgart-Zuffenhausen was still under American control, Ferry Porsche’s school friend Albert Prinzing had already done some groundwork in Stuttgart. The Porsche villa in Killesberg served as his first home and the first car bodies were built at the Reutter coachworks in Augusten-Strasse in early 1950. Ferry Porsche later summed up the time in Gmünd with wonder: ‘Today I am amazed that we managed to produce so many cars, given all the problems that there were.’

Source: Porsche website